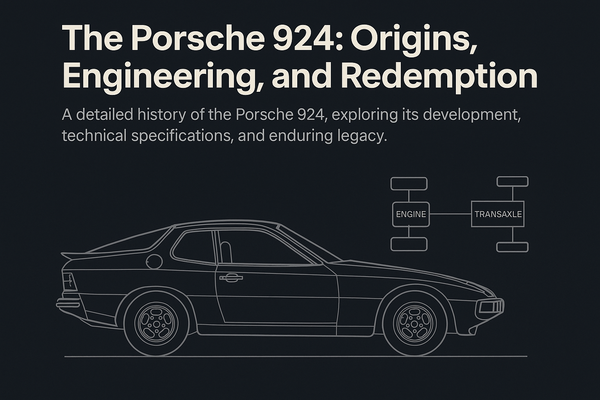

C694 FWT - Work From January to Now

Carburettor conversion with a custom intake, rust repairs, suspension refresh, brake overhaul, and fibreglass prep — C694’s coming together, piece by piece.

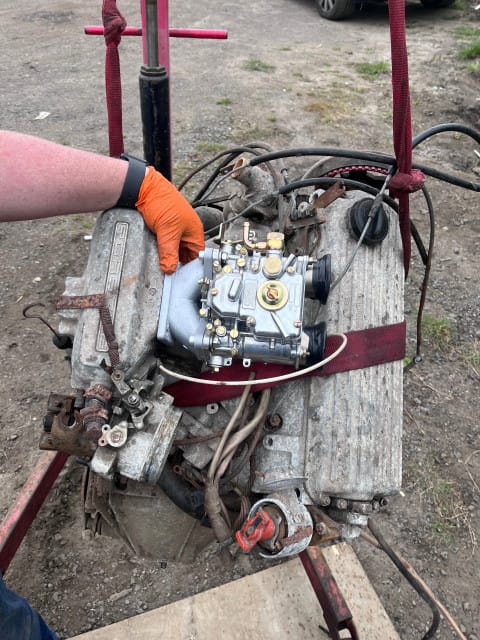

Carburettor Conversion

- Why carbs? After the K-Jet was stolen for the other 924 (I never really intended on using it anyway.), I opted for a Weber DCOE 45 mm carb.

- Custom intake adapter: Carbs on an automatic are challenging as you lose the kickdown pully which is attached to the stock intake manifold. All the 3rd party carb manifolds use twin DCOEs or quad bike carbs – I want to keep some form of fuel economy so I Instead recruited a friend to design and 3D-print a PTEG adapter to replace the throttle body with a DCOE utilising the entire stock intake manifold, confirmed it held up under rough tuning, then I ordered final version printed in SLM aluminium—following an example from a 924 Safari in the US - there wasn't much info on the conversion although there are videos of the car driving and it seems to work well.

Check out the first start on the new carb setup below!

Sourcing Parts from HAH 462Y

I Acquired a parts car: HAH 462Y was an ex-BRSCC race 924. I stripped its front end, suspension, engine, and gearbox—selling unneeded bits to a fellow 924 OC member.

I scrapped the Shell: Although its tub was rock-solid (no welding needed), I lacked space to swap bodies, so the shell went for scrap although the majority of the useful parts were used to save many other 924s, the shell was used for body cuts to fix rust on other cars so not entirely wasted.

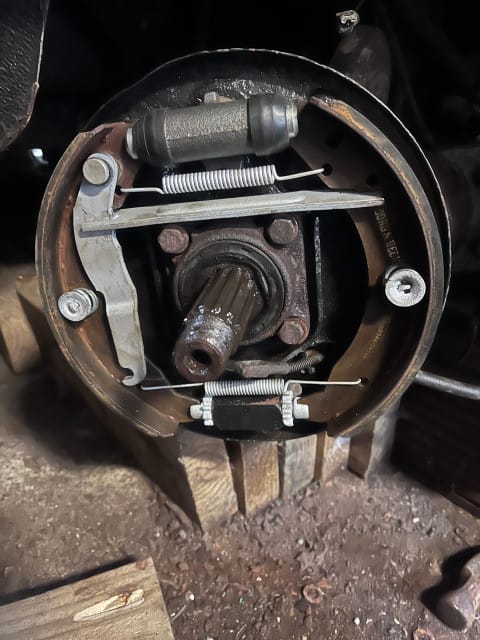

The parts rescued from HAH 462Y, full almost new rear brake assemble, stiffer anti roll bar, cross member, steering rack and a set of click adjustable LEDA suspension.

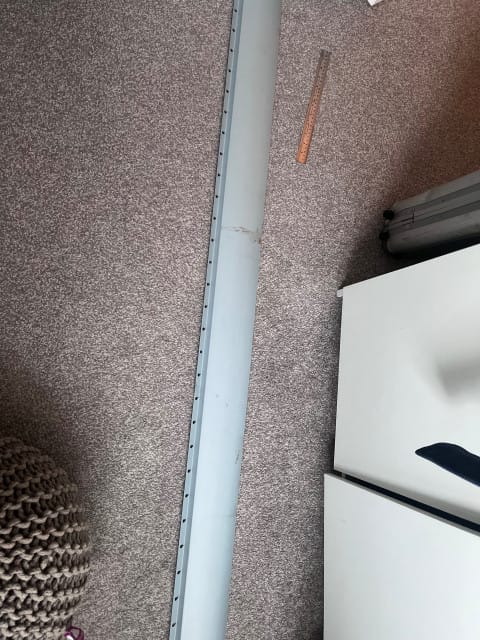

Rust Repairs & Suspension Refresh

- “Holy rust, Batman!” Removing old wings revealed rot in the sills, front suspension mounts, and the tub-to-floor seam.

- Welding: I cut out the rotten metal, welded in new sections, then installed fresh front suspension components sourced from HAH 462Y.

New sill installed and fitted. These are available new from brickwerks and fit perfectly. My welding is still a little rough at this point but its strong enough with good penetration.

Brakes & Interior

- Rear brakes: Fitted new backing plates, shoes, and hardware.

- Front calipers: Stripped, cleaned, painted, and prepped for installation this weekend.

- Seats: Collected a set of rear seats so I can at least make a start on the interior.

The Pasha rear seats were purchased from the same guy that bought the remains of HAH 462Y, calipers were built with new seals and given a fresh coat of paint.

Body Panels & Paint

- Fibreglass panels: Prepped and painted a colour close to Miami Blue—yes, the car’s getting a full colour change!

- Bonnet restoration: The toughest task—four days of paint stripper, sanding, gel-coat repair, and repainting to remove hundreds of layers of old finish.

Where We Stand & What’s Next

C694 FWT now has a near completed carb conversion, refreshed brakes and suspension, mostly solid welded structure, and the start of new body work.

Over the coming weeks I’ll fit the front calipers, install the new aluminium intake adaptor, get the new body panels on, complete a few small bits of welding and bleed the brakes. I plan to have the car on the road sometime in August - a deadline that will almost certainly slip.